RULES FOR SANDWICH PANELS

- Identify the product you want, whether it is for wall or roof use

- Identify aesthetic and architectural needs according to the project, choosing a customized product from the assortment of “TESLA PANELS”

- Identify the structural needs according to the project, choosing the customized product and related fasteners after analyzing the load resistance

- Identify the fire resistance requirements for the type of panel you are interested in

- Identify the wall thermal/sound insulation requirements in terms of energy efficiency and savings

- Identify the best surface according to the degradation resistance of the exposed surfaces to maintain the structure durability

- Check that the delivery terms and quality standards of the panels are compatible with the project and site requirements

- Assign the installation phase to experienced and qualified personnel or a company to ensure that the installation is carried out properly and in accordance with the installation instructions

- Ensure that the standards for handling and storage of the panels specified by “TESLA PANELS” have been met

- Identify the correct and adapted maintenance and inspection plan to ensure proper durability of the structure according to the rules of “TESLA PANELS”.

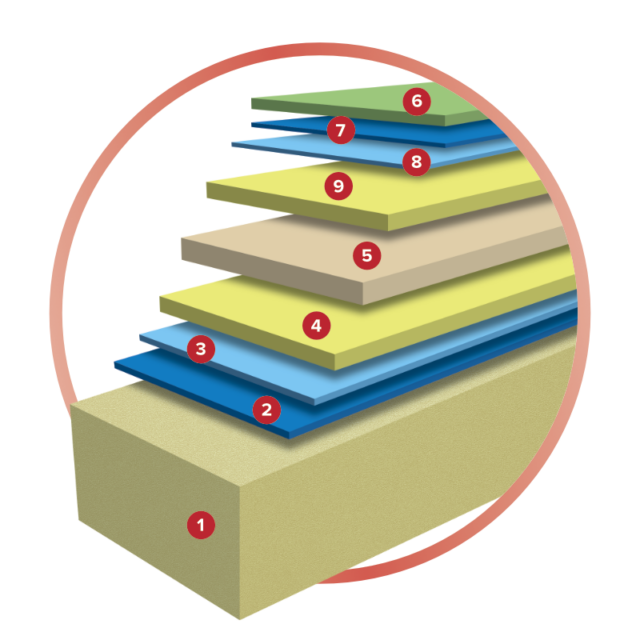

ROOF THERMAL INSULATION SANDWICHDESCRIPTION OF PANEL SHEETS

Galvanized laminated sheets consist of steel, a base with a galvanized coating, a surface layer, a paint called a primer and a final coating called a finish.

1. Polyurethane foam

2. & 7. Primer

3. & 8. Pre-treatment

4. & 9. Galvanized layer

5. Steel

6. Galvanized primer for pre-treatment – top layer

TYPES OF LAMINATION AND METHOD OF USE

The end user or architect may choose the basic characteristics of the panel according to our catalogue, as well as the type of color and quality of the base according to their requirements and the type of panel.

The choice of organic coating and its color must be adequate for the final use of the product.

TESLA PANELS can offer a wide range of metal surfaces:

- Hot-dip galvanized sheets of various galvanizing ranges

- Natural or painted aluminum

- Stainless steel

Galvanized laminated sheets are part of the constructive features of the panel and, thanks to the steel quality, significantly contribute to panel durability, protecting the insulating core and ensuring a unique aesthetic value to the panel and the facility on which it is mounted.

Galvanized laminated sheets are part of the constructive features of the panel and, thanks to the steel quality, significantly contribute to panel durability, protecting the insulating core and ensuring a unique aesthetic value to the panel and the facility on which it is mounted.

Environmental changes, together with the increase in industrial production and urban pollution, have made it necessary that a greater resistance to corrosion be insured compared to natural materials, and for this reason different solutions are available for every requirement and project.

“Tesla Panels“ products are made of galvanized laminated sheets as described in the diagram. The quality of the organic coating of galvanized sheets must be selected depending on the environment in which the panel will be installed.

For more information, contact our professional associates.