INTRODUCTION

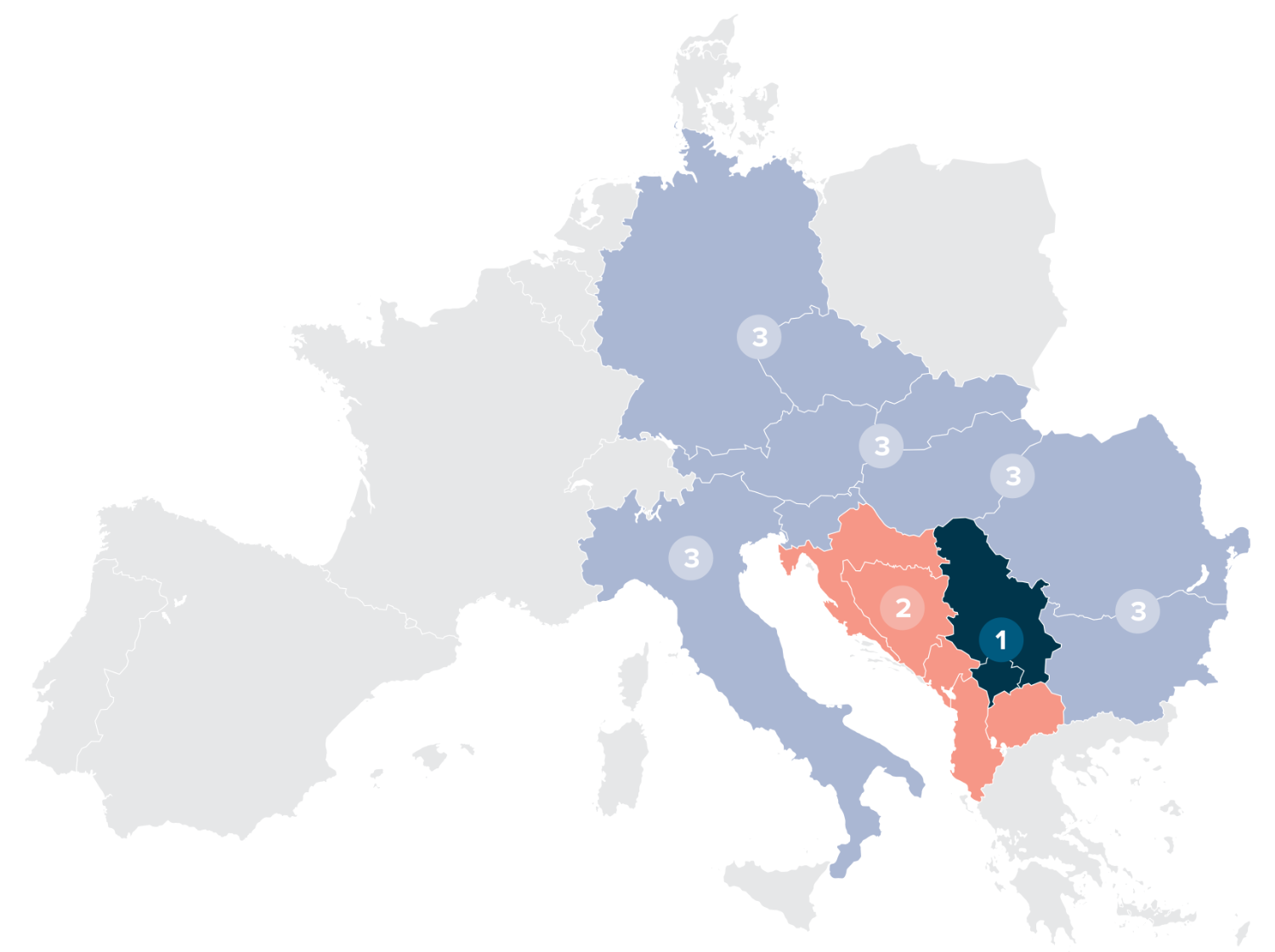

Jugometal d.o.o. (Ivković Investment Group) was founded on January 5, 1990. That same year they began their cooperation with Smederevo Steel Plant – Železara Smederevo d.o.o. (HBIS GROUP Serbia Iron & Steel). Thanks to the years of continuous investment in the development of the company, people and market, today we represent the leading service center and the largest distributor in the field of laminated and galvanized color coated sheets on the Serbian market, with a long-lasting partnership with the world’s largest factory, “Maanshan Iron & Steel”. The company has successfully positioned itself not only in the Western Balkans, but also in other countries of the Southeast European region.

Today’s market requires continuous growth and development. Investing in innovations is imperative for a sound and sustainable company development. As a logical part of the company’s development strategy, we decided to take a new step and start investing in thermal insulation materials in the construction industry, which represents the company’s new development strategy. In 2020, we have invested in the production of sandwich panels and the creation of a completely new brand, “TESLA PANELS”, which is rapidly leading the future of modern construction.

PLANT LOCATION

AND CHARACTERISTICS

“The application of sandwich panels is most common in logistics centers, shopping parks, shopping malls, modern residential and commercial buildings“

GOALS

With this investment in the most modern sandwich panel plant in Southeast Europe, and with further continuous investments in thermal insulation materials, we want to position the “TESLA PANELS“ brand as a leader in Southeast Europe in this industry by 2027.

STRATEGY AND INNOVATIONS

Product testing in accredited laboratories ensures high material quality standards, at the same time promoting the latest trends in chemical industry for the production and increasing application of sandwich panels for our consumers.

The production of ''TESLA PANELS'' is in perfect harmony with the environment. The panels consist of laminated sheets on both sides, an insulating core made from polyurethane or mineral wool, which are produced on the state-of-the-art lines in this industry thus allowing us to guarantee a low environmental impact.

In addition to the existing production, ''TESLA PANELS'' also plans to install a solar power plant to provide enough electricity for production that will have a favorable environmental impact.

APPLICATION

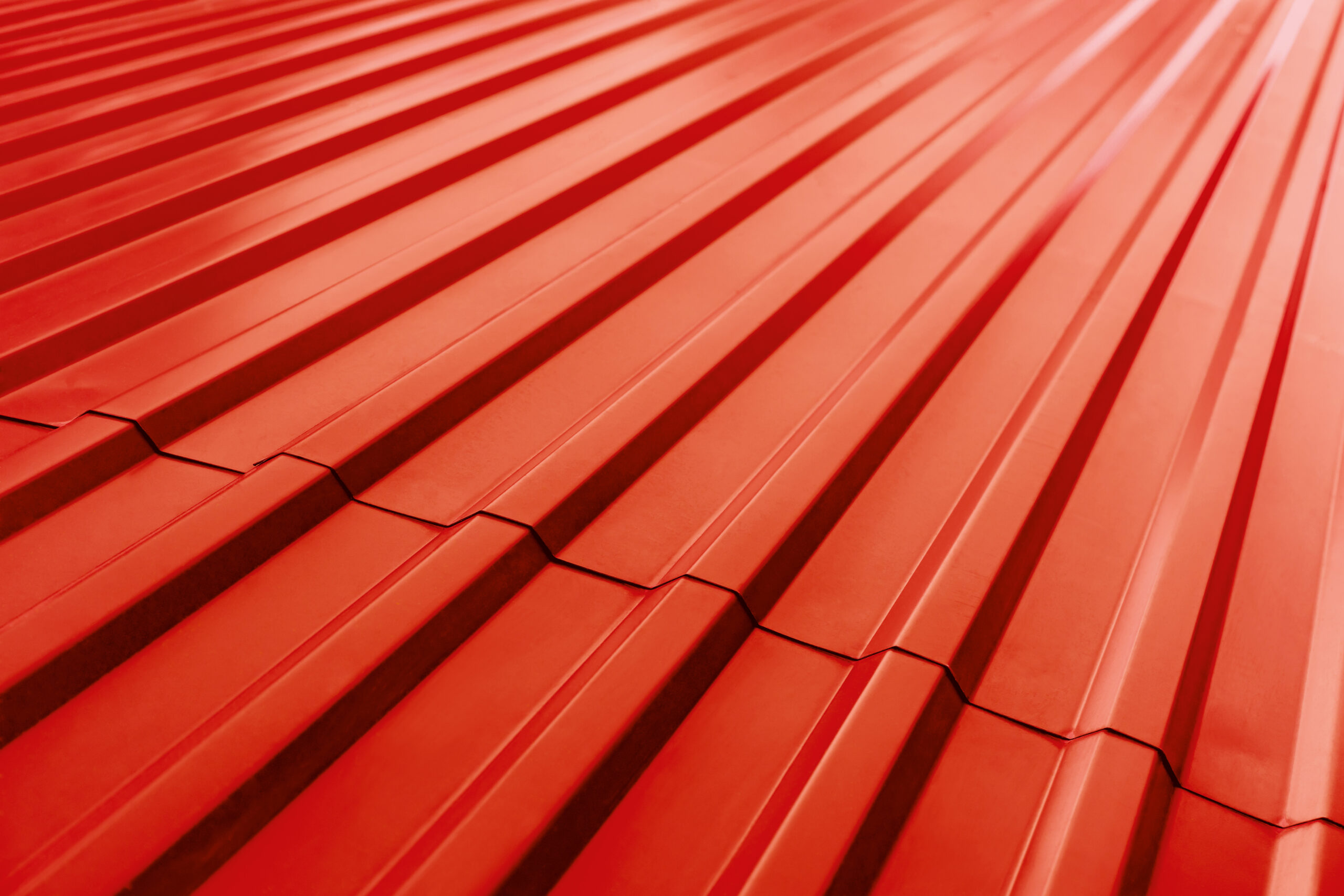

The application of sandwich panels is most common in: logistics centers, shopping parks, modern factories, shopping malls, cold storage rooms, business facilities, medical centers and many other similar facilities. Due to their good thermal insulation properties and the quality of the construction itself, not only are they a material that can be installed quickly, but they also regarded as money-saving by investors.

“The Company has successfully positioned itself in Croatia, Bosnia and Herzegovina, North Macedonia, Montenegro and Albania“.

QUALITY

Our plant will produce panels with length ranging from 2 m to 15 m and thickness from 30mm to 200 mm, depending on customer requirements.

Cutting-edge materials and raw materials from renowned global and European suppliers are used in the production, which guarantees high quality and product characteristics.

The main features of the panel are:

- Thermal insulation

- Fire resistance (PIR panels), Mineral wool panels

- Sound isolation

- Fast construction

We achieve high quality, reliability and safety by complying with the following standards:

- EN 14509:2014 European standard that defines the quality of production, the quality of the manufactured panel and the safety of the panel for use.

- ISO 9001:2015 is an internationally recognized standard that provides a framework for implementing a quality management system.

- ISO 14001:2015 international standard that requires that organizations address environmental issues.

- ISO 45001:2018 occupational health and safety management system.

- ISO/IEC 27001:2013 information security management systems.

Your trust is our imperative

The technical instructions and guidelines of TESLA PANELS should be adhere to for storage, transport and installation of facade and roof panels. In particular, you should consider the following:

- Mechanical damage to panels permanently impairs the aesthetic appearance of the facade

- The protective film on the surface of the panel can be damaged if exposed to UV rays and heat

- Remove the protective film immediately before or after installing the panel, failure to comply with the recommendations results in failure to remove the film from the panel surface.

- To cut panels only use scissors and special tools for panel cutting.

- Grinders, drills and similar tools must not be used for panel cutting the use of which results in overheating of the sheet or the creation of filings that cause damage to the sheet protective layer and cause corrosion at the damaged spot.

- Roof panels are attached with self-tapping screws exclusively on the ribbed part using storm washers.

- The screws must be optimally fastened to avoid panel deformation,

- It is mandatory to install EPDM tapes on the joints of the roof panels (folds),

- In order not to damage the aesthetics of the facade, when installing the panels, take care of the width of the grouts, dilatations, and joints.